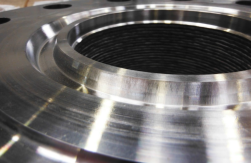

- Cladding TIG / MIG

– TIG with hot wire weld deposit for higher bonding response to base material as per MPS and approved WPS/PQR – material: 316 / Duplex / Super Duplex / Incolloy 825, Inconel 625 …

– Groove sealing area cladding by total filling of the groove before machining

– Verification of Fe dilution at 3 mm below surface, acceptance criteria as per MPS (5 or 10% max Fe content)

– Bore cladding: as clad condition within imposed tolerances (full bore machining upon request)

– Sealing area and face cladding 100% machined before testing

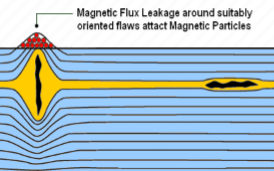

– 100% inspection of clad area by Ultrasonic tests / X-Ray / Dye Penetrant Test

– Application of repair procedure as and when required